Emil hired two of his students from Bar-IIan University to work on the 3D CAD system.ĪutoCAD from Autodesk was then only a 2D CAD system. So, he bought two IBM PCs, with financing from his father, to develop the software. When the IBM-PC was launched in 1982, Emil decided to start his own company to develop CAD/CAM software for the Windows PC environment. After finishing his doctorate, Emil started teaching part-time at the Computer Science Dept at Bar Ilan University.

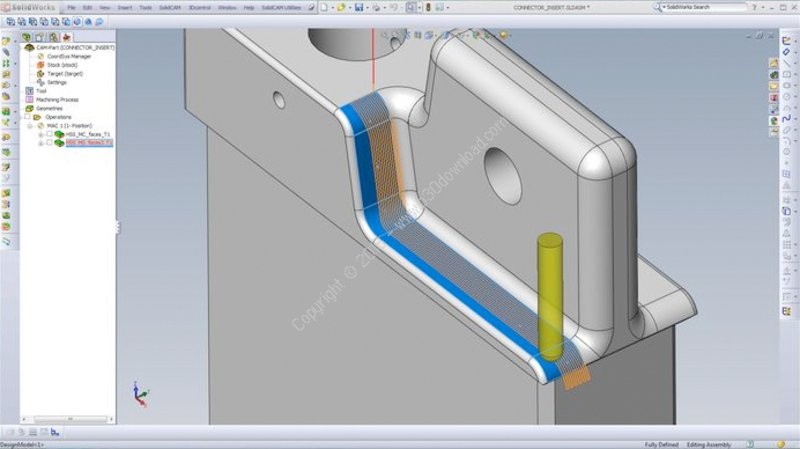

While working in the aerospace industry, Emil Somekh has continued with his research work for his doctorate at the Technion. SolidCAM supports all CNC machine brands for 2.5D Milling, 3D Milling, 5X Milling, Turning, Multi-Channel Mill-Turn, and Swiss machining.Įmil Somekh was working in a big aerospace company, developing various CAD/CAM products. 4/5 axes Milling, Turning and Multi-Channel Mill-Turn, for Multi-Turret, Multi-Spindle and Swiss type CNC machines.The company’s current product is SolidCAM – a CAM system for manufacturing, integrated into the major CAD systems, SolidWorks, and Inventor. Supports all CNC applications, including iMachining 2D, iMachining 3D, 2.5D Mill, 3D Mill/HSM, Indexial and Sim. iMachining technology saves 70% and more in machining time and dramatically extends the cutting tools life.Seamlessly integrated in Inventor, with full toolpath associativity to the Inventor model.Watch the InventorCAM Professor videos as you evaluate the InventorCAM functions. Download and experience the benefits of the powerful InventorCAM solution. InventorCAM offers a free full version 60-day trial. InventorCAM provides the best solution for Multi-Channel Mill-Turn and Swiss CNCs, with easy and flexible CAM programming, excellent multi-channel synchronization, full machine simulation and certified posts for all complex CNC brands. The patented iMachining is completely unique both in its toolpath and its unique Technology Wizard, that automatically calculates the optimal cutting conditions, taking into account the toolpath, stock material, cutting tool and CNC machine parameters. The InventorCAM iMachining technology provides immense savings and increased efficiency in your CNC milling operations.

The tight integration with Inventor streamlines the design-to-production life cycle. InventorCAM is seamlessly integrated in Inventor and has full toolpath associativity to the Inventor model. InventorCAM is an Integrated CAM for Autodesk ® Inventor ® and it revolutionizes CNC milling with its unique iMachining technology - saving 70% and more in machining time and dramatically extending the cutting tools life.

0 kommentar(er)

0 kommentar(er)